Pipe bursting and pipe splitting are trenchless methods used to replace existing pipelines in the same alignment without physically removing the existing pipeline. Bursting and splitting by using the exiting alignment to replace a pipe avoids the need to secure additional right-of-way to install the replacement pipe. Bursting and splitting can be used to up-size the pipeline increasing its flow capacity.

Pipe bursting was initially developed in the 1980's to replace small diameter cast iron gas distribution lines, but has since grown in acceptance as an effective method for replacing pipelines diverse in size, material type, and function including water, sewer, or gas pipelines.

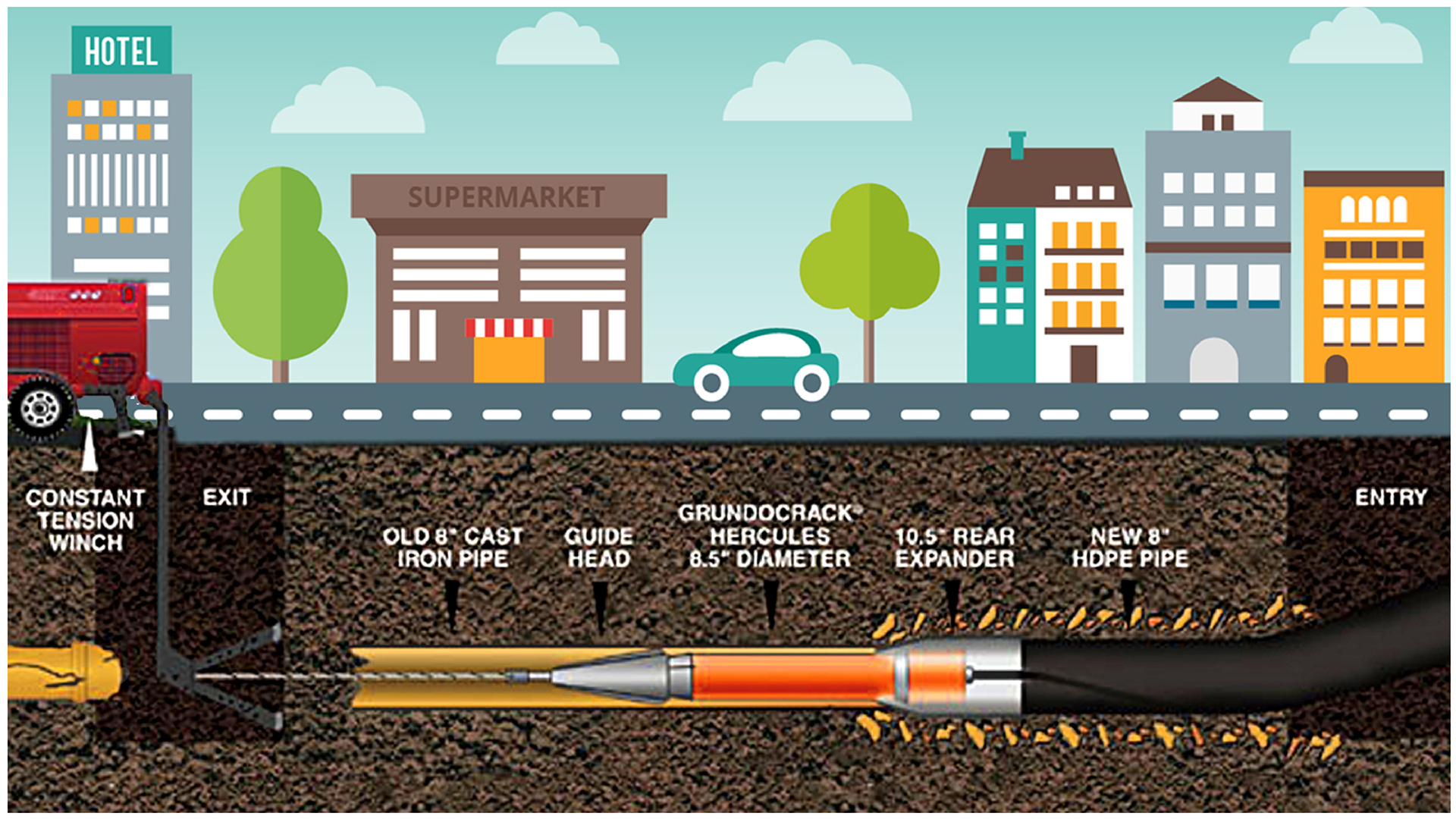

Pipe bursting is used to replace brittle pipes such as clay, concrete and cast iron through the application of a static or pneumatic bursting head to fragment the existing pipe. Simultaneously, a new product pipe attached to the back of the bursting head is installed in the same alignment as the original pipe.

The pipe bursting process consists of advancing a conical-shaped bursting head that has a diameter 50 to 100 mm larger than the new replacement pipe, through the existing pipe. The radial expansion caused by the geometry of the bursting head surmounts the host pipe’s tensile and shear strength capacities, resulting in the fragmentation or splitting of the pipe. As the bursting head is pulled through the host pipe, the fragments are pushed into the resulting annulus, creating a cavity for the product pipe. The product pipe immediately follows the bursting head as it is simultaneously pulled or pushed into the newly formed cavity.

The suitability of employing pipe bursting depends on numerous factors including burst length, host pipe material, up-size diameter, and geological conditions. For sewer replacement, burst lengths are generally 50 to 100 m, which is the typical distance between manhole locations in a built up municipal setting. Potable water replacement projects typically involve installing new lines of 200 mm, 250 mm, or 300 mm between valve locations. The majority of pipe bursting is employed for up-sizing from 150 to 200 mm, 200 mm to 250 mm or 250 to 300 mm.

Pipe splitting uses the same principles as pipe bursting to replace pipes that require cutting such as steel, ductile iron and plastic pipe. A typical pipe splitting head uses cutters or blades to slice the host pipe while an expansion shell head peels open the host pipe providing space for the new product pipe.